Industrial Precision CNC Machining Services

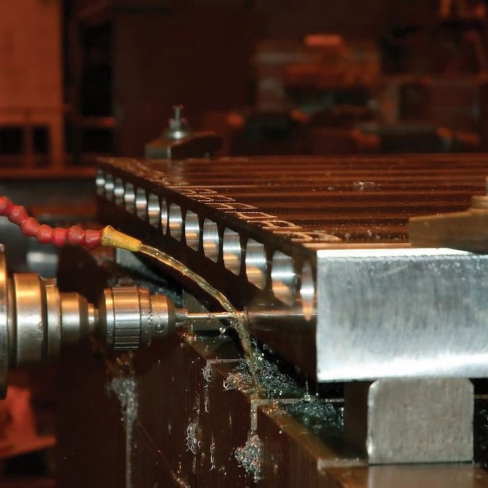

Turning

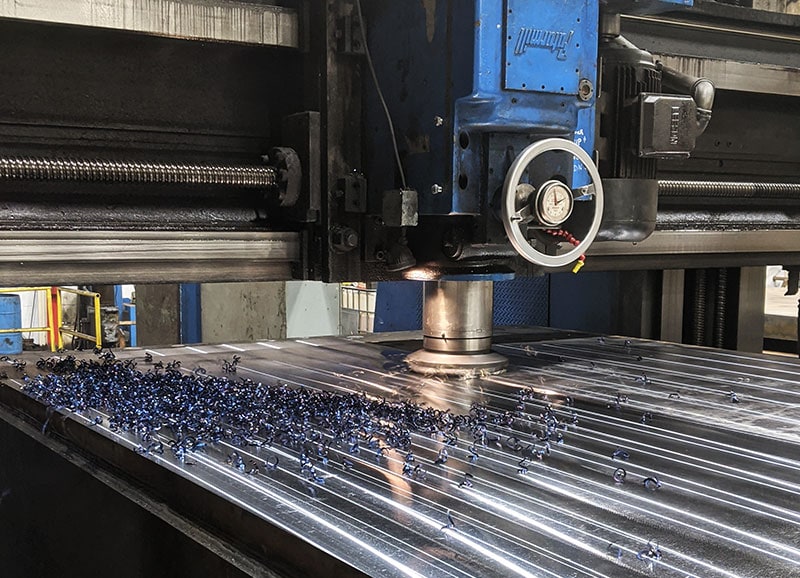

Milling & Boring

Drilling, Tapping, Threading, Reaming, & Grooving

Grinding

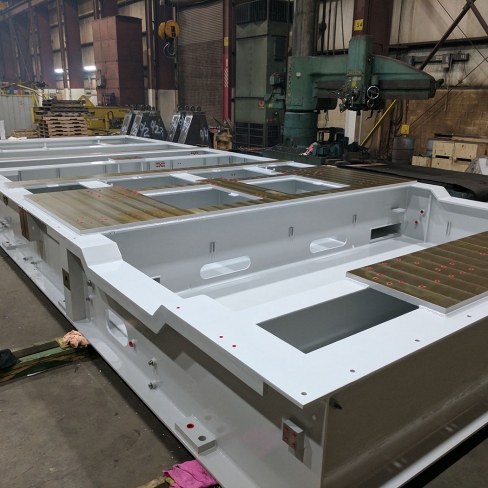

Large Scale Heavy Industrial Contract Machining

ISO Certified Contract CNC Machining Services in Erie, PA

Custom Engineering continually invests in the latest technology and training for our highly skilled machinists. We specialize in large scale heavy industrial machining projects exceeding 720” long and 186” wide in a variety of materials, including alloy steel, carbon steel, stainless steel, aluminum, copper, and more. We produce components using these materials in heavy industrial applications for baseplates, sole plates, heated platens, bolsters and more. Our technology allows us to hold tight tolerances on features including perpendicularity, flatness, and parallelism, per customer specifications.

Capabilities

Manual & CNC Machining Capabilities

- Planer Mills

- Horizontal Boring Mills (HBM)

- Vertical Bridge Mills

- Vertical Machining Centers (VMC)

- Line Boring

- Deep Hole and Gun Drilling

- Radial Drilling

- Blanchard/Rotary Grinding

- Precision Surface Grinding

Machinery & Equipment

| Make | Type | X-Axis | Y-Axis | Z-Axis | W-Axis | Table |

| Gray | Planer Mill | 365 | 147 | 10 (102 Under Rail) | N/A | 132x364 |

| Niles | Planer Mill | 306+ | 185 | 10 (116 Under Rail) | N/A | 132x364 |

| Niles | Planer Mill | 240 | 73 | 8 (69 Under Rail) | N/A | 64x241 |

| Niles | Planer Mill | 150 | 97 | 8 (72 Under Rail) | N/A | 84x146 |

| Gray | CNC HBM | 240 | 120 | 48 | 40 Table Feed | 110x110 / 108x168 |

| Toshiba | CNC/HBM | 236 | 98 | 39 | 78 | 98x78 |

| G&L | CNC HBM | 108 | 72 | 36 | 48 | 48x120 |

| G&L | HBM | 169 | 69 | 48 | N/A | 110x192 |

| G&L | HBM | 158.3 | 90 | 48 | N/A | N/A |

| Cincinnati Gilbert | HBM | 65 | 60 | 24 | 24 | 48x48 |

| SNK | CNC/HMC | 118 | 78 | 63 Column | 27.5 Spindle | 63x71 |

| Visionwide | CNC/VMC | 204 | 153 | 40 | N/A | 196x96 |

| Amera-seiki | CNC/VMC | 204 | 79 | 35 | N/A | 65x204 |

| Cincinnati Gilbert | CNC/VMC | 120 | 30 | 114 | N/A | 28x157 |

| Haas | CNC/VMC | 40 | 20 | 25 | N/A | 18.5x48 |

| Cincinnati Gilbert | E Mill | 117 | 30 | 14 | N/A | 30x108 |

Large Scale Milling and Boring

Custom utilizes a wide range of precision machines, including planer mills, CNC vertical machining centers, and horizontal boring mills, with a wide range of envelopes. Our experienced craftsmen routinely machine precision base plates, heating platens, bolsters, fixtures and other industrial components with capabilities for essentially any operation requiring milling, boring, drilling, slotting, and keyway cutting.

- Visionwide Bridge Mill:

- 204” x 102” max capacity

- SNK Horizontal Machining Center:

- 118” x 78” max capacity

- Niles Planer Mill:

- 610+” x 182” max capacity

- Toshiba Horizontal Boring Mill:

- 700” x 120” max capacity

Large Scale Industrial Surface Grinding

Custom Engineering offers multiple styles of large scale surface grinding for a variety of materials. We use Blanchard grinding to provide an excellent quality finish that will meet your exact specifications. Our skilled operators are able to provide precision flatness and parallelism to dimensions of .001” and thickness to +/- .0005”.

Blanchard/Rotary Grinding:

- 72” rotary table

- 84” swing

- 22” height

With over 50 years of experience in precision surface grinding, the experts at Custom Engineering use Supertec horizontal surface grinder to deliver extreme precision flatness and parallelism with a smooth finish to large surface area projects accommodating parts as large as 80” wide, up to 118” long, with height up to 18”.

Precision Surface Grinding:

- 40” width

- 120” length

- 18” height

CNC Turning Centers with Live Tooling

Custom utilizes Computerized Numerical Controlled (CNC) turning centers, which allow for precision facing, turning, boring, threading, drilling, grooving, trepanning, and milling operations. Our equipment offers a 4 axis turning center, allowing all 2 axis functions normally associated with turning centers to be executed with two turrets simultaneously, as well as turning centers equipped for large diameter work up to 40”. Custom offers speed and precision with Live Tool capacity, which adds the ability to perform mill type operations without need for additional setup and handling, improving the quality and cost of your heavy industrial fabrication.

- Okuma V100R

- Chuck Size: up to 40”

- Working Envelope:

- X-axis travel range: up to 40”

- Z-axis travel range: up to 36”

- Okuma LB3000EX II

- Live Tool Lathe

- Max Turning Diameter: 13.39”

- Max Turning Length Between Spindles: 32.18”

- Working Envelope:

- Y-axis travel: 4.72” (+2.76/-1.97)

- W-axis travel (Sub-Spindle): 35.24”

Precision Deep-Hole Drilling

Custom offers a comprehensive range of drilling, tapping, reaming, threading, and grooving services. Using the unique process of deep-hole drilling to produce long and accurate holes with a smooth finish, Custom’s capabilities and equipment allow for drilling holes ranging from 0.25”-2” in diameter and up to 20’ in length with unmatched accuracy and precision.

Our wide range of operations and technology accommodate simple and complex designs, allowing for increased capacity, shorter lead times, versatility, and reproducibility.

- 6-Axis Drilling and Machining Center

- 87” x 79” Rotary 6-Axis Table

- 2.36” Max Diameter x 78.74” Drilling Depth

- 30-Position Automatic Tool Changer

- BTA

- 0.25”-2” Diameter x 20’ Drilling Depth

Contact us Today for any of your Precision Machining Needs

Gallery

Contact us Today to Speak with One of our Specialists

"*" indicates required fields