Capabilities

Certifications & Registrations

- ISO 9001:2015 Certified

- ASME Section IX

- AWS Certified

- NADCAP Accreditation

- ITAR Registered

- AQS-AC7004 Aerospace Accreditation

- ASME (U & S Stamps)

- National Board R Stamp

- NAP-23/AEA Approved Supplier

- NAICS Codes: 332312, 332710, 332313, 332420, 333249, 336419 and DUNS 077495232

Custom’s Staff & Team

- 140+ Employees

- 30+ Skilled Machinists

- 30+ Certified Welders

- Certified Welding Inspectors (CWI) and Welding Engineers On-Site

Manufacturing Space

200,000 sq. ft.

Crane Capacity

160,000 lbs

Precision Fit-Up Solutions

- Ensures a level surface for large scale weldments

Robotic Welding System

- 3 bay motoman system

Welding Processes

- 180 Welding Procedures

- Robotic

- Semi-automatic

- Manual Welding

- Gas tungsten arc welding (TIG)

- Gas metal arc welding (MIG)

- Flux cored arc welding (FCAW)

- Submerged arc welding (SUBARC)

- Shielded metal arc welding (STICK)

Machinery & Equipment

| Make | Type | X-Axis | Y-Axis | Z-Axis | W-Axis | Table |

| Gray | Planer Mill | 365 | 147 | 10 (102 Under Rail) | N/A | 132x364 |

| Niles | Planer Mill | 306+ | 185 | 10 (116 Under Rail) | N/A | 132x364 |

| Niles | Planer Mill | 240 | 73 | 8 (69 Under Rail) | N/A | 64x241 |

| Niles | Planer Mill | 150 | 97 | 8 (72 Under Rail) | N/A | 84x146 |

| Gray | CNC HBM | 240 | 120 | 48 | 40 Table Feed | 110x110 / 108x168 |

| Toshiba | CNC/HBM | 236 | 98 | 39 | 78 | 98x78 |

| G&L | CNC HBM | 108 | 72 | 36 | 48 | 48x120 |

| G&L | HBM | 169 | 69 | 48 | N/A | 110x192 |

| G&L | HBM | 158.3 | 90 | 48 | N/A | N/A |

| Cincinnati Gilbert | HBM | 65 | 60 | 24 | 24 | 48x48 |

| SNK | CNC/HMC | 118 | 78 | 63 Column | 27.5 Spindle | 63x71 |

| Visionwide | CNC/VMC | 204 | 153 | 40 | N/A | 196x96 |

| Amera-seiki | CNC/VMC | 204 | 79 | 35 | N/A | 65x204 |

| Cincinnati Gilbert | CNC/VMC | 120 | 30 | 114 | N/A | 28x157 |

| Haas | CNC/VMC | 40 | 20 | 25 | N/A | 18.5x48 |

| Cincinnati Gilbert | E Mill | 117 | 30 | 14 | N/A | 30x108 |

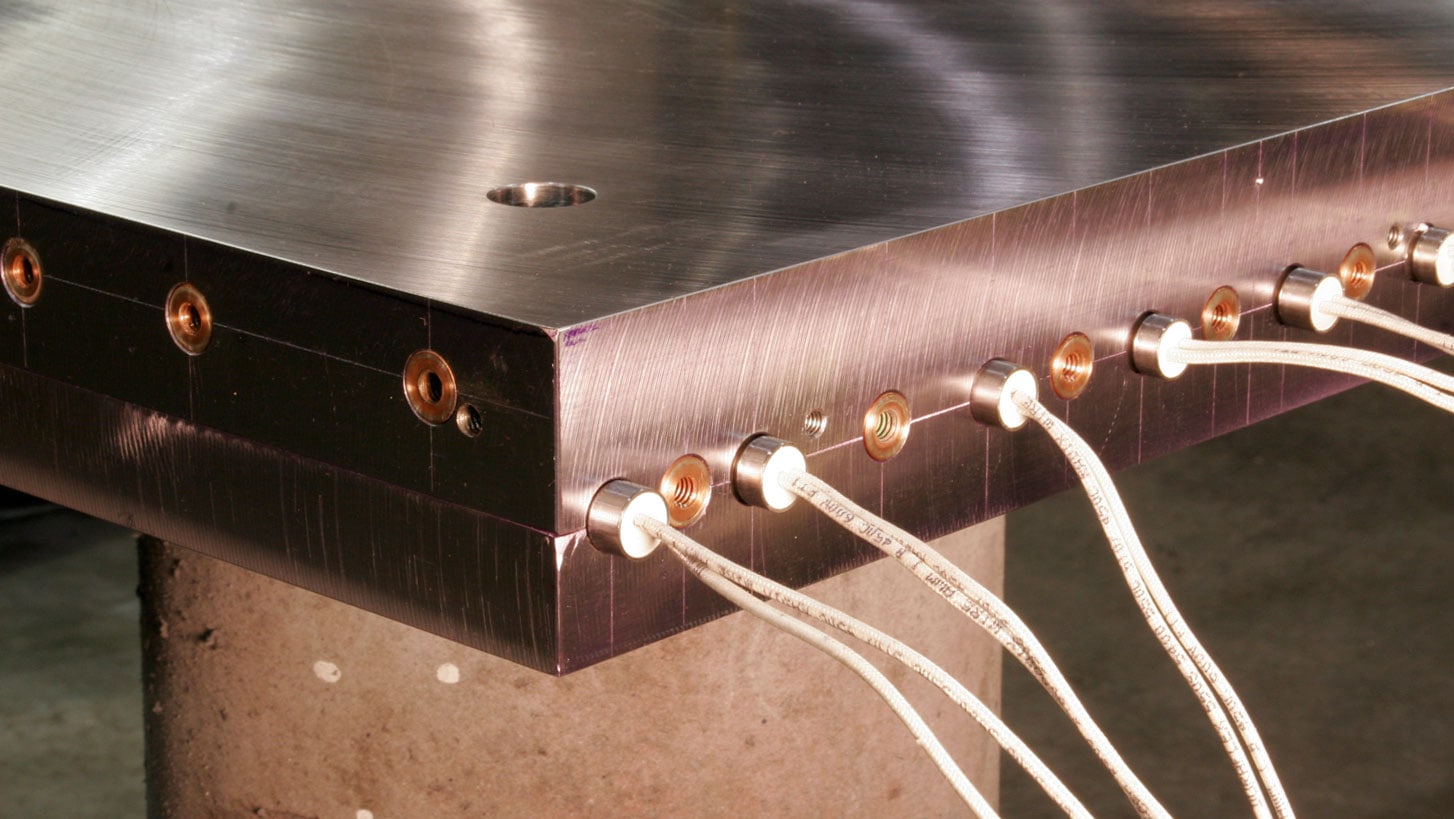

Heating Platens

- Wood panel products

- Industrial and decorative laminating

- Rubber molding

- Conveyor belting

- Composite paneling

- Armor

- Metal hot forming

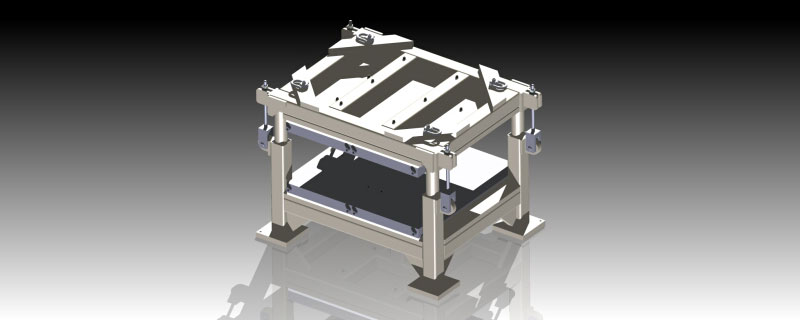

Platens Overview

Platen Design

Platen Refurbishing

Platen Types

Request a Heated Platen Quote Today

Hydraulic Presses

- Felt or foam fabrication

- Rubber molded mats

- Hot form pressing

- High pressure laminating

- Composite material manufacturing and fabrication

- Honeycomb panel manufacturing

- Phenolic panel manufacturing

Hydraulic Presses Overview

Press Engineering & Services

Request a Hydraulic Press Quote Today

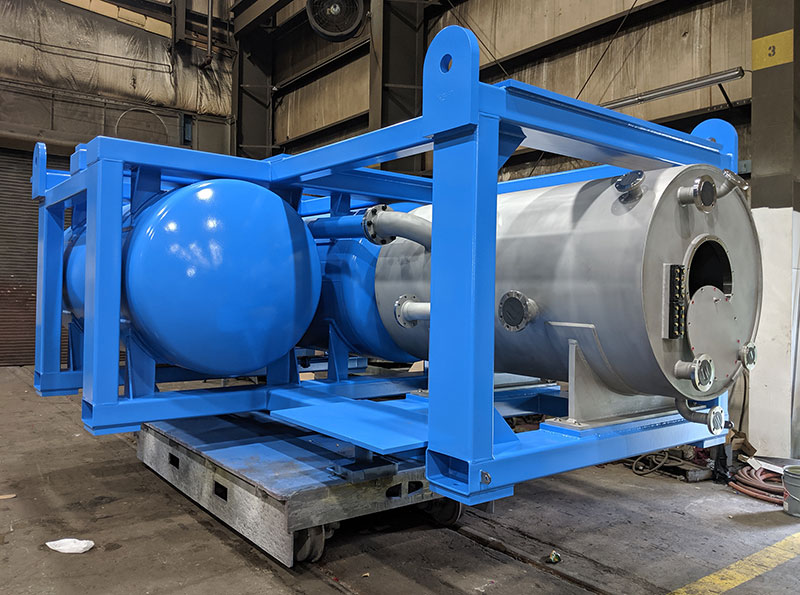

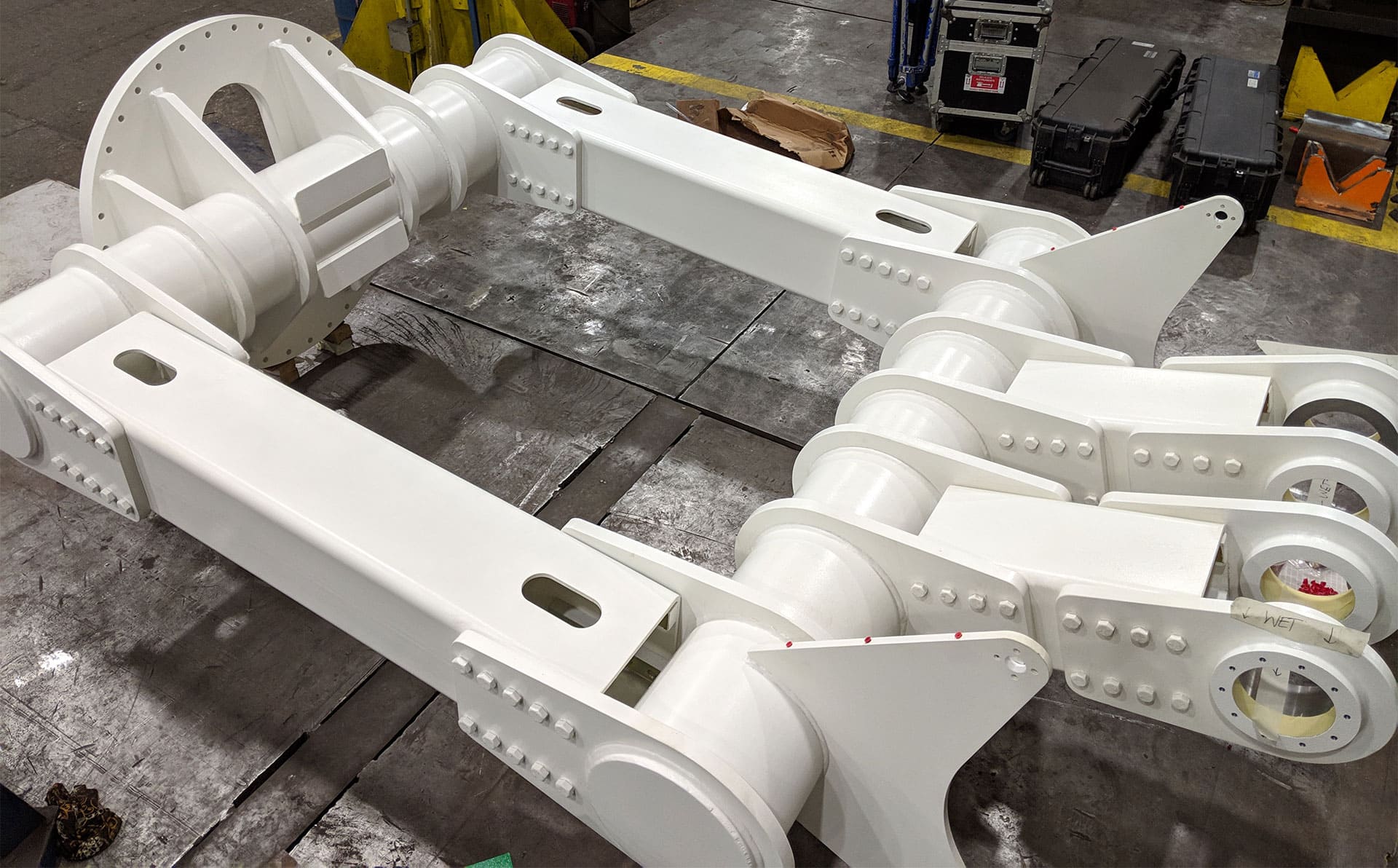

Metal Fabrication

Heavy Weldments

Complex Fabrications

Heavy Duty Baseplates & Skids

Pressure Vessels

Request a Metal Fabrication Quote Today

Certified Welding

Custom Engineering employs a team of highly skilled craftsmen to provide unmatched skill and expertise in multiple forms of welding including GMAW, FCAW, SAW, GTAW, and SMAW. Custom maintains over 180 qualified welding procedures, qualified in accordance with ASME Section IX, AWS D1.1, AWS D1.6 and other various Codes of Construction.

Our manufacturing facility is specially designed to produce mid to large scale metal fabrications, accommodating weldments up to and over 60’ long and weighing up to 160,000 lbs. With the combination of ingenious precision fit-up fixtures, multiple burn tables, robotic welding capabilities, ASME and AWS certified welders, Custom meets the highest quality standards for large fabricated components and is able to hold tight tolerances.

Robotic Welding

Material Processing

Precision Fit-Up

Industrial Metal Finishing

Request a Welding Quote Today

Precision Machining

Turning

Milling & Boring

Drilling, Tapping, Threading, Reaming, & Grooving

Grinding

Request a Precision Machining Quote Today

Contact us Today to Speak with One of our Specialists

"*" indicates required fields