Platens Overview

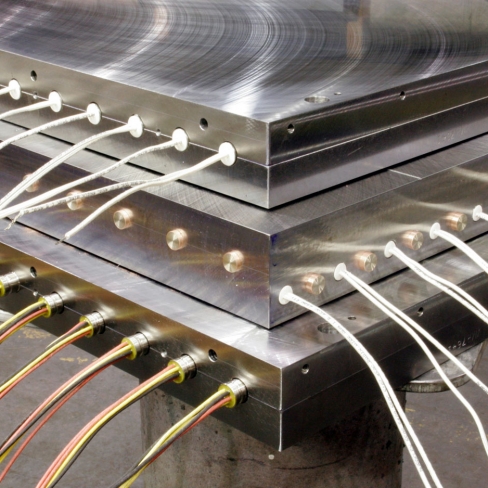

Platen Design

Platen Refurbishing

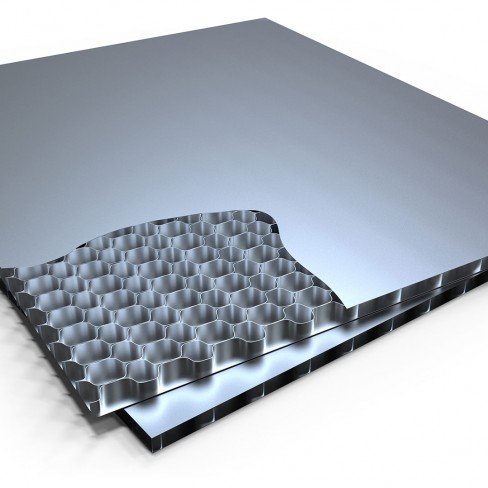

Platen Types

The World Leader in Heating Platens

Large Industrial Heating Platen Manufacturing

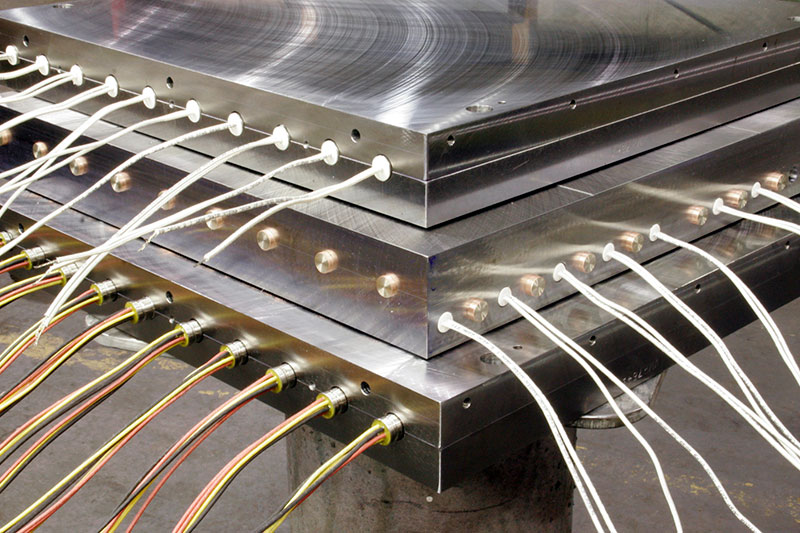

Custom Engineering is a world leader in heated platens manufacturing, and is the leading manufacturer of heating platens in North America with 65 years of platen manufacturing experience. Hydraulic platen presses are used in industry to manufacture a myriad of different products. The sizes and applications for platens are as varied as the products they produce. We make platens as small as 12” square for laminating applications, as wide as 15 ½’ for producing oriented strand board (OSB), and as long as 60’ for manufacturing conveyor belting. Custom Engineering can manufacture the largest platens in the world.

Tailored Platen Design and Engineering in Pennsylvania

Custom Engineering uses innovative technology and manufacturing expertise to produce platens specifically tailored to customers’ requirements. Rubber products are produced on steam heated platens. Wood panel products are made using thermal fluid (Hot Oil) platens. Molded products are cured using steam, fluid and electric heat. Temperatures range from 200°F (water glycol) to 350°F (steam) to 450°F (thermal fluid) and up to 1800°F (electric). The specific application determines the heat source.

NAICS Codes: 326199, 326299, 321999, 333249

Custom provides platens for all types of industries including:

- Wood Panel Products

- Industrial and Decorative Laminating

- Rubber Molding

- Conveyor Belting

- Composite Paneling

- Armor

- Metal Hot Forming

Typical Heating/Cooling Sources of Platens:

Electric | Steam | Water | Thermal Fluid

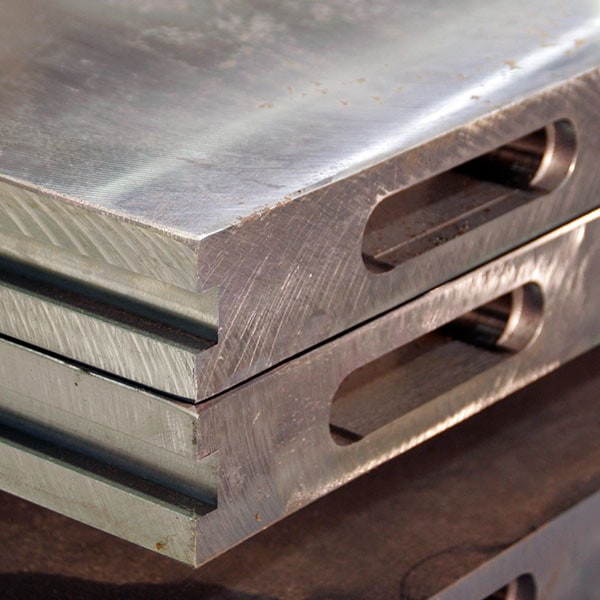

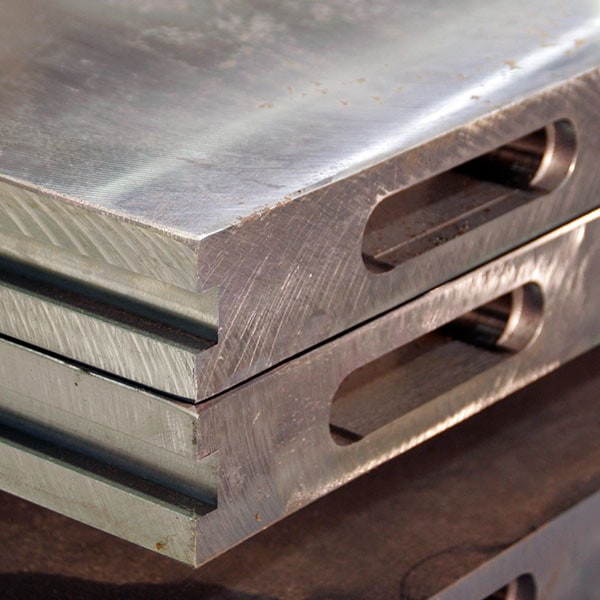

Industrial Platen Refurbishing and Repair Services

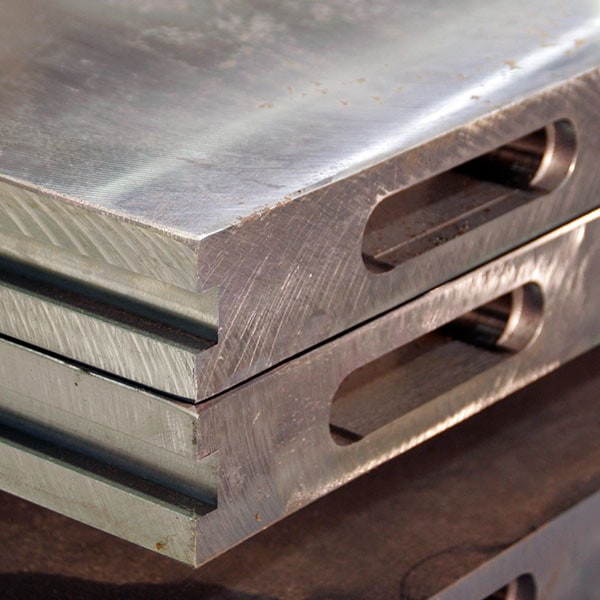

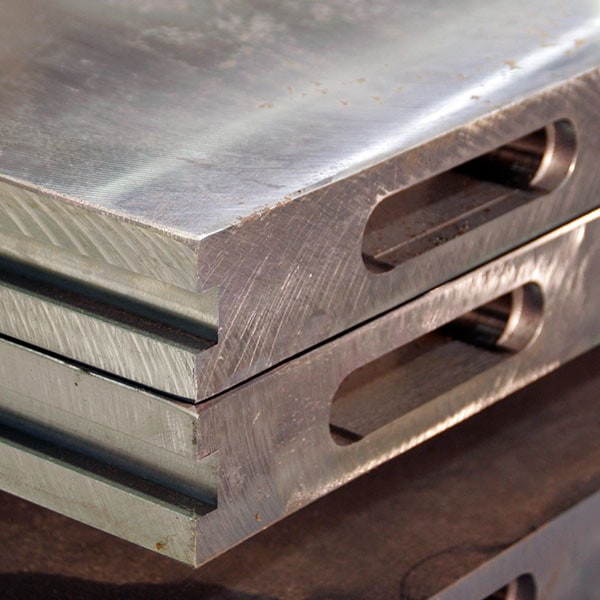

Maintaining platen flatness and parallelism is critical to operational efficiencies. When platens become nicked, bent, gouged, or damaged, they will produce imperfections in the end product. Custom offers a complete refurbishing program to:

- Re-machine platens that have been damaged in pressing accidents

- Restore flat and parallel specifications to platens slightly mis-shaped from normal wear and tear

- Modify platens for heating with fluid instead of steam

- Upgrading hanger and guide systems to accommodate additional press openings

Platens for All Types of Presses

Increase Productivity

Complete Restoration

Test Reports Provided

Superior Hydraulic Press Replacement Platens

Custom Engineering’s refurbishing program restores platens for nearly every make of hydraulic press, regardless of the original manufacturer. An obstruction in the flow pattern can cause temperature inconsistencies of controlled temperature platens, thus leading to production issues. We provide a complete refurbishing and replacement program for uninterrupted production and increased productivity. In some cases, replacement may be needed to supply all new platens, new step hangers, and additional guides to increase the number of openings in a press.

Contact us Today for any of your Heating Platens Needs

Gallery

Industries Served

Choosing the Best Heating Platen Type for My Applications

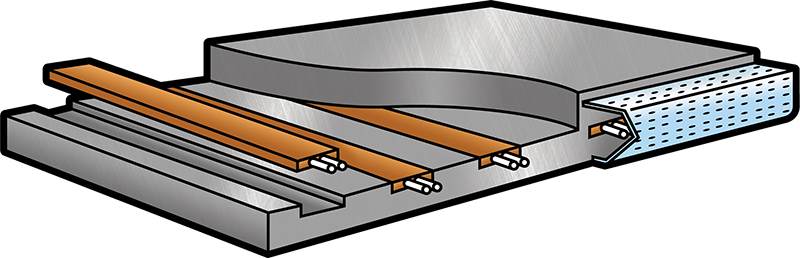

Configuration is important when determining what type of platen is needed for your application. Determine whether your application needs platens that heat only, or requires both heating and cooling. Consider which method of heating is required; oil, water, steam, or electric.

The charts below show the differences between electrically heated platens, thermal fluid heated platens, water heated platens, and steam heated platens.

If you have a hydraulic press and are unsure of your platen type, please contact our sales department. Call 814.898.2800 and ask for Andy Tompkins

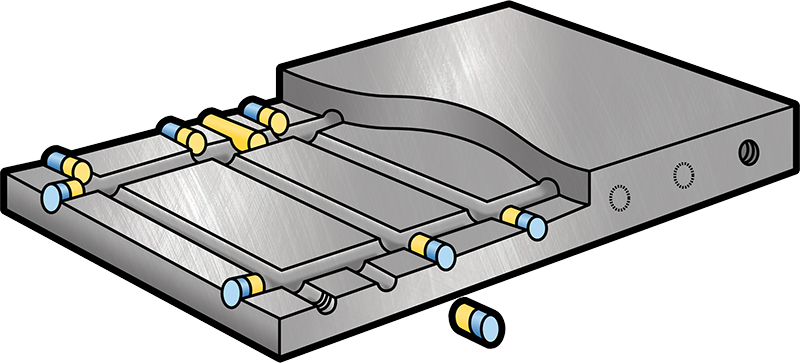

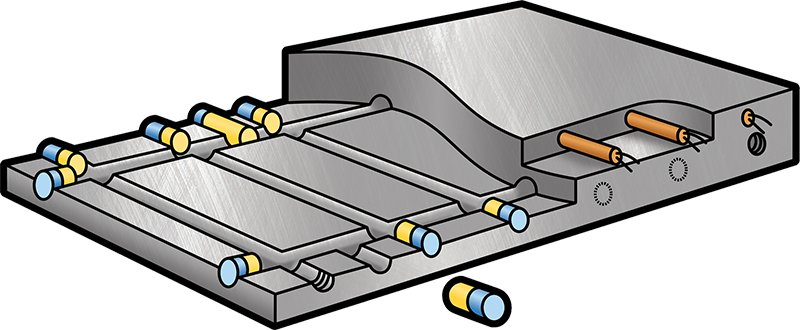

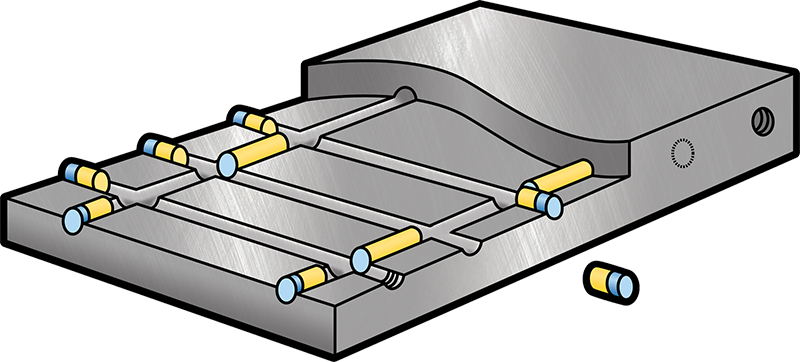

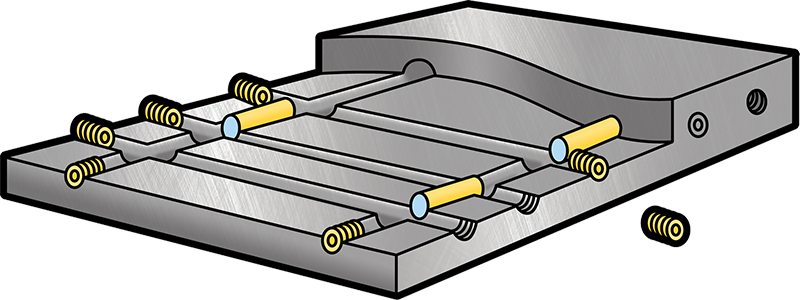

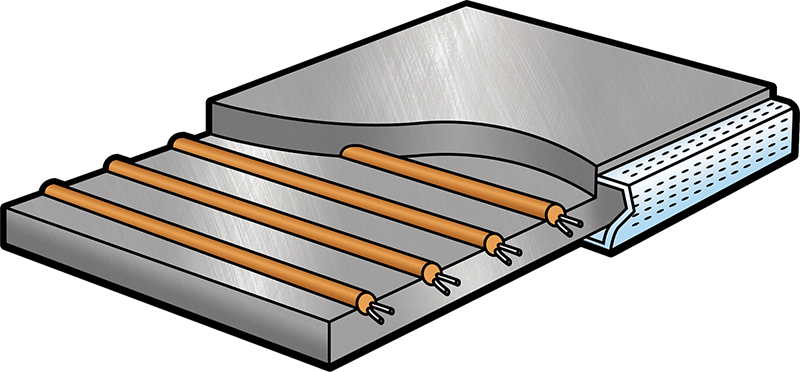

Type A - Electric Strip Platen

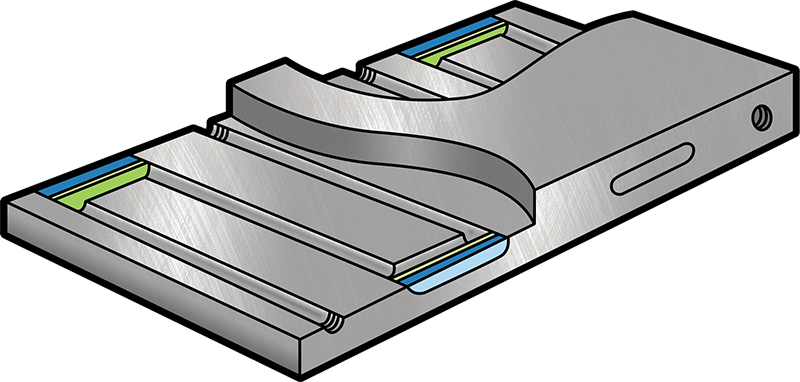

Type B - Steam, Water, or Thermal Fluid Platen

Type C - Electric Cartridge Platen

Type B - Steam Platen

Type D Edge Pin - Steam, Water, or Thermal Fluid Platen

Type E - Electrical Cartridge Platen

Type M - Steam, Water, or Thermal Fluid Platen

Related News

There are no related events or news at this time, please check back later to stay up to date with Custom Engineering Co.

Contact us Today to Speak with One of our Specialists

"*" indicates required fields